It’s been a little over a month now since all the Kickstarter Kits made their way out into the wild, with some already getting close to the final assembly! I’ve seen very few set-backs or issues from shipping aside from a couple delays with the units that went to Germany, but other than that, all seems to be good!

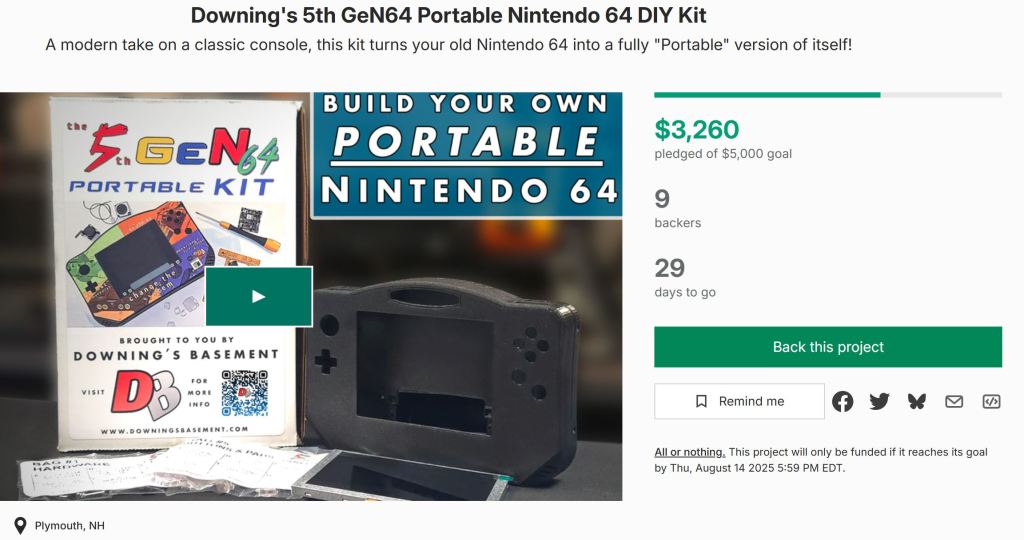

So what’s next? Well for the past few weeks I have been working in preparation for Round 2 of the kits themselves as well as trying to get a bit more organized with my inventory, because as the title eluded too, I have finally opened up an online shop for all things related to The 5th GeN64 Portable Kit project!

Though very (very) basic in nature, the idea here was to have a single location where those who funded the Kickstarter could get spare parts if needed but also have a place where the actual kits could be Pre-Ordered for the next batch. Though I’m still kind of figuring this out as I go, the first test purchases have been made and it seems to be a remarkably simple process.

When Can I Access The Store?

Pre-Orders for Batch 2 and general access to the store will open up on Saturday, February 14th 2026. (please make good decisions on this day and don’t piss off your significant other with this, I don’t need that kind of blood on my hands) The Batch 2 Pre-Order will remain open until March 14th, 2026 or until the batch limit of 20 Kits is met. The store itself will remain open permanently.

It is important to note that I’m only doing these kits in batches of 20 at a time as I can simply not let it take over my life more than it already has, but more importantly, it keeps the production manageable and within a decent timeline. The other reason why I can’t produce these ahead of time is I simply cannot afford to bring in the parts needed without orders for them that are guaranteed.

How Will Pre-Orders Work?

As mentioned, general Pre-Orders will open up on Feb. 14th and be open through March 14th or until the 20 kits have sold out. If you do purchase a kit but need to cancel for whatever reason, you can do so, up to the point the when the pre-orders close. At this point they become Non-Cancelable/Non-Refundable, simply because the money goes directly to parts and materials I need to order to produce them.

After the Pre-Orders close, there is a 45 to 60 day production window that is based on the assumption that nothing get’s held up. Chances are this round is going to go a lot smoother than the Kickstarter backers had to endure, but such is the way when the trail has already been blazed. Which also means the lead time may be considerably less, but I have to give it a reasonable window to cover that “just in case” situations.

Updates on progress or set-backs will be made both via the emails provided at purchase and on my Discord which I encourage you to join!

Placing Your Pre-Order

The store is very basic and is still a work in progress, and because I’m basically just on a “Trial” plan, I don’t get all the functionality of the higher tier plans, which means I can’t group things the way I’d like to. But, that’s a small worry for another day.

To place your Pre-Order, simply navigate to the kit and it walks you through the rest! The only thing is to make sure you leave a message to the seller (me) to let me know which Decal you want for the front face, otherwise it will ship with the default “OG Brushed Aluminum” image.

I Live Outside The USA, Why Can’t I Order A Kit Through The Store?

Though I understand this is an inconvenience, after a few scares with International shipping with the Kickstarter, I feel there is just too much risk using common carriers and customs. It’s just not worth the gray hairs. However, what I have had great luck with International shipping is the use of “Freight Forwarders”, which basically allows me to ship to a collection point in the US and they take care off all the shipping, customs forms and tracking. The only downside is the person receiving the shipment must have the account.

So, if you’re interested in a kit and are over seas, please just hit me up through the contact form at the bottom of the page HERE

I Missed The Pre-Order! What Happens Now?

Worry Not! As like with those who missed out on the Kickstarter, the next batch of Pre-Orders are scheduled to open up in May 2026, with the same deal of 20 Kits and general lead times. The plan is to do this until the 100 unit max has been reached, at which point they will be gone, but we’ve got all of 2026 to get through before that happens.

But make sure you get on the waitlist as those on it will be given first priority and early access to the Pre-Order Batch! Simply send me a message using the form at the bottom of the page HERE and I’ll get you on it!

So thank you again so much for all your interest in this project and in picking up a kit! It’s been a wild ride that I hope to continue to 100, but if you have any questions, feel free to reach out!

Thanks Again!

Downing